Welcome to The

Indica Experience Center

Welcome to The Indica Experience Center

Fact:

of transformational projects fail in the cannabis industry.

Fact:

84% of transformational projects fail in the cannabis industry.

This is largely due to two things:

Click each box to learn more

Lack of Alignment

Alignment is more than making sure your lights work with your sensors or that your software vendor shares your values. It’s understanding and predicting the ripple effects across an organization from a technology or process change and preemptively planning for contingencies. When this is overlooked, projects fail before they even start.

Improper Change Management

Vendors are often unqualified or unaware of the effects an operational change could create within a licensed cannabis business, causing technology adoption failures during trials and implementations that derail what could be a successful solution for an operator – Costing everyone time and money. Or worse, the solution provided isn’t compliant with the varying regulations throughout the hundreds of micro-markets resulting in a complete disaster for both vendor and operator.

This is largely due to two things:

Click each box to learn more

Lack of Alignment

Alignment is more than making sure your lights work with your sensors or that your software vendor shares your values. It’s understanding and predicting the ripple effects across an organization from a technology or process change and preemptively planning for contingencies. When this is overlooked, projects fail before they even start.

Improper Change Management

Vendors are often unqualified or unaware of the effects an operational change could create within a licensed cannabis business, causing technology adoption failures during trials and implementations that derail what could be a successful solution for an operator – Costing everyone time and money. Or worse, the solution provided isn’t compliant with the varying regulations throughout the hundreds of micro-markets resulting in a complete disaster for both vendor and operator.

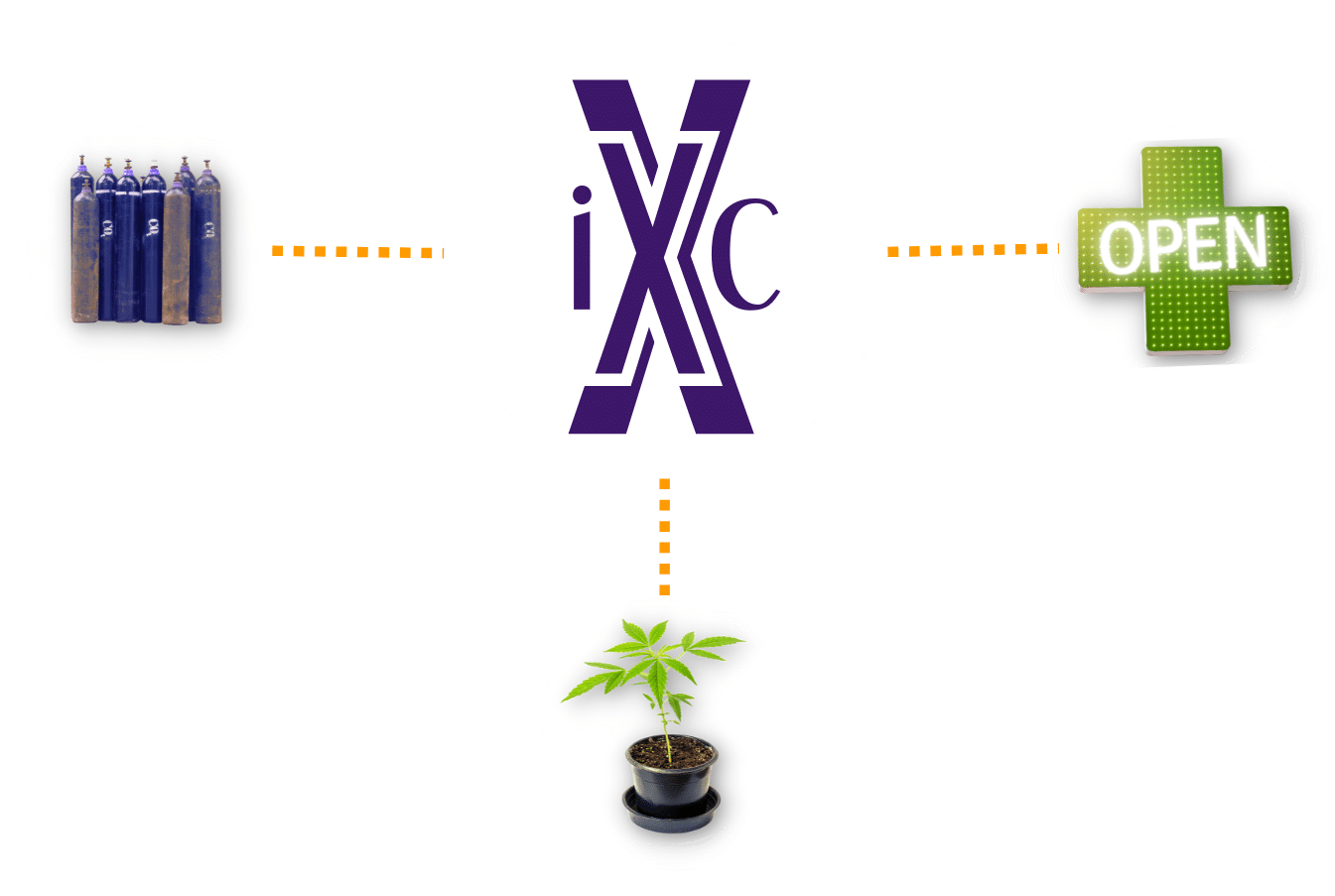

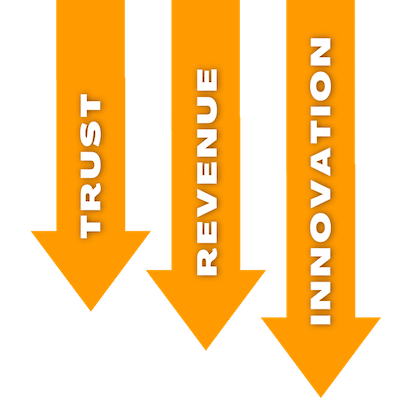

Lack of alignment and improper change management have caused a tremendous distrust of vendors, their solutions, and at times entire areas of technology.

That causes longer (and more expensive) sales cycles for vendors and hampers cost saving innovation for operators.

There needs to be a bridge that connects these worlds.

There needs to be a bridge that connects these worlds.

The Indica Experience Center

Validating Technology for the Cannabis Industry

Our 10,000 sq. ft. Research & Development facility in Austin, TX, independently validates technology for operational innovation while experientially showcasing these solutions to the Cannabis Industry.

A first of its kind solution for the rapidly expanding cannabis industry, the IXC is focused on providing premium services that bridge the gap between technology companies and licensed operators.

Harnessing a think tank of over 50 subject matter experts, we continuously gather data related to production factors while analyzing the real world TCOGS of technology optimization solutions.

Through agnostic analysis, we develop scalable processes that optimize technologies for cannabis and hemp operators before they implement them which significantly mitigates risk and drastically increases successful adoption of technology.

The Indica Experience Center

Validating Technology for the Cannabis Industry

Our 10,000 sq. ft. Research & Development facility in Austin, TX, independently validates technology for operational innovation while experientially showcasing these solutions to the Cannabis Industry.

A first of its kind solution for the rapidly expanding cannabis industry, the IXC is focused on providing premium services that bridge the gap between technology companies and licensed operators.

Harnessing a think tank of over 50 subject matter experts, we continuously gather data related to production factors while analyzing the real world TCOGS of technology optimization solutions.

Through agnostic analysis, we develop scalable processes that optimize technologies for cannabis and hemp operators before they implement them which significantly mitigates risk and drastically increases successful adoption of technology.

How?

The project will occur in 3 phases...

The project will occur in 3 phases...

Phase I

Proof of Concept

The goal of Phase One (8 mos) was to create an autonomous horticulture environment that optimized scalable production. By building two small chambers within a 10,000 sqft greenhouse, each containing the same unique cultivar as a control, we used hardware and corresponding software to affect environmental factors and gather data from different technologies on the cultivars growth factors. We successfully developed a unique technology recipe that lowered production cost while increasing yield by 13x.

Phase 2

We Are Here (1-12 months)

The goal of Phase Two is to establish and expand a data driven experience center to both research and showcase validated technology solutions for licensed operators and educate government officials & lawmakers.

Phase 2

We Are Here (1-12 months)

The goal of Phase Two is to establish and expand a data driven experience center to both research and showcase validated technology solutions for licensed operators and educate government officials & lawmakers.

Phase 3

Expansion

The goal of Phase 3 (12-36 months) will be to expand the experience center from cultivation to also include processing / manufacturing and retail environments to create a vertically integrated technology validation ecosystem.